Design

problems from Thermodynamics II

(Northwestern

University)

Making Sure it's not the Heat, but the Humidity...

Putting the Ozone Back Where it Belongs

You are Director of New Engine Development for the Fjord Motor Car Company, and the CEO has just given you a mandate to develop a no-holds-barred sports car. Missam Motors has just introduced the Anaconda, a mid-engine design built around the Medusa, a sixteen cylinder engine with eight turbochargers, and the Vice-President of R&D for Fjord has decided that the only way Fjord can top this is with a gas-turbine-powered car. The new car, code named FireArrow, needs a specification for its engine. Unfortunately, Marketing has gotten involved, and as usual has bollixed things up. They want to make the following claims about the engine:

Since you have to shoehorn this engine into a sports car the first claim clearly makes sense. However, you have a meeting with the Director of Marketing next week in which you'll have to explain why the other two claims are problematic.

To make your case create a simple gas-turbine cycle in CyclePad. Use a cooler to represent the atmosphere. Since it's the atmosphere, choose air as the substance. An ambient pressure of around 1 bar will do nicely, and you can assume that the ambient temperature (i.e., the temperature both of the cooler and of the stuff entering the compressor) is 72°F, since Fjord expects to sell eight out of ten FireArrows in California. Using ultra-premium gasoline, you can achieve 1800°F in the burn-cans of the engine, which will heat the air entering the turbine to 1500°F. Assume this engine will develop 400hp. Assume that all components are ideal.

Finally, choose a reasonable value for the pressure ratio across the compressor, say between 3 and 30.

Using the sensitivity analysis tool, determine the relationship between the compressor's pressure ratio and (a) the thermal efficiency of the engine and (b) the required mass-flow (which will in large part determine the size of the engine). From this information, decide on the optimal compression ratio for the compressor.

Having done so, develop a concise, qualitative argument for why this is the optimal compression ratio and why the Marketing Department should back off on its claims of fuel-efficiency and compression.

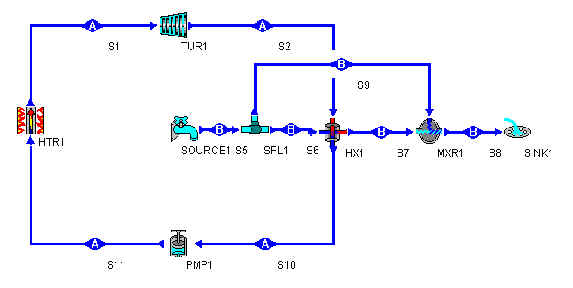

You have been charged with the construction of a new power plant to supply 100MW of baseload power to Ecoawareville, Montana. The Ecoawe river is really not much more than a stream, and during times of dry weather, its flow can decline to as low as 50,000 lbs/sec. However, it's the only source of cooling available for your power plant, so a site on the river has been selected and approved by the town council. Your job is to construct a vapor power cycle. The best turbine available has a shaft power of 100 MW, a maximum inlet temperature of 1000°F and maximum inlet pressure of 1200psi. The Ecoawe is fed by mountain runoff, so it never rises above 59°F, which makes it an ideal habitat for the rare back-flipping trout. A downstream temperature rise of more than 4.0°F (i.e. a temperature over 630 F) will endanger this trout, and the citizens of Ecoaware will be swift to demand your head on a platter. Past experience has also shown that algae blooms occur if the discharged cooling water is greater than 75°F. (Assume atmospheric pressure for the river). The water at the turbine outlet must be at least 90% vapor to avoid turbine damage.

Set up a simple vapor cycle that uses a heat-exchanger as its condenser. Model the river using a source and a sink and use a splitter and direct a flow of cooling water through the heat-exchanger. You will need to specify that the flow fraction of the stuff exiting the source is 1.

Report on the highest thermal and Carnot efficiency you can achieve given the above constraints and on the relationship between the turbine outlet pressure and its waste heat discharge.

Hints:

You are the Chief Engineer for Warza, Inc, a major builder of power plants, and the City of San Diego has asked you to investigate the feasibility of building a Ocean Thermal Energy power plant. The Pacific off the San Diego coast has a surface temperature of 27°C and a temperature at a depth of 600 ft of 5°C. The plant should generate 100MW of power. Assume that you need at least a 3°C difference for reasonable heat transfer rates between the sea water and the working fluid.

Using a simple vapor power cycle (ie, only use four components, a heater, a turbine, a cooler, and a pump), investigate at least two different working fluids (R12, R134a, R22 or ammonia).

Hints:

Answer these questions:

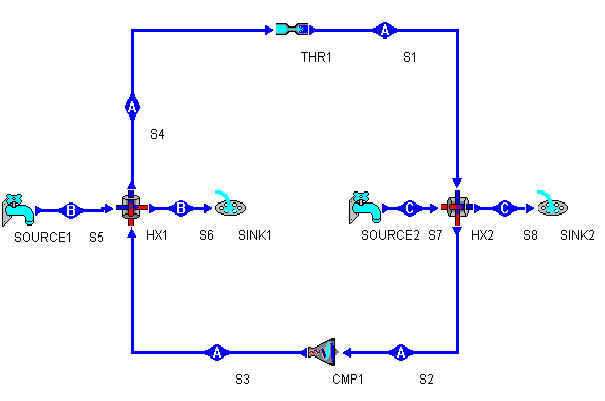

You are the Director of Product Development for ChillemGood, a leading manufacturer of refrigerators. An entrepreneur has approached the Director of Marketing with an idea for making a large refrigerator (meat locker?) that use all-natural, sparkling water in place of refrigerant-12. This entrepreneur claims that such a refrigerator would take less energy to operate. The President of ChillemGood wants your evaluation of the feasibility of this design.

Set up a simple vapor compression cycle using four components and R-12 as its working fluid in CyclePad. Assume that all components are ideal. The stuff in the refrigerator is to be kept at 42°F, and ambient room temperature is 72°F. The compressor is finicky about wet vapor, so make the stuff entering it saturated with a quality of 1. The stuff entering the throttle is saturated liquid. For sub-cycles B and C assume a Volume flow of 0.25 ft3/s for the air. Try an initial pressure ratio (PR) of 5 for the compressor.

You will also need to make some assumptions about temperature. Assume that the refrigerator is cooling from 500 F to 420 F. You will also need to assume a temperature for the stuff entering the throttle. This will need to be above room temperature. Likewise, the stuff exiting the throttle needs to be cooler than 420 C.

Then, as a separate system, set up another cycle using water as its working fluid. (be sure to save your R12 cycle!) In this cycle, do not specify a phase for the stuff entering the throttle. You may also want to retract your assumption about the compression ratio before switching to water.

Answer the following questions:

1. Compare the mass flow of the two cycles. Which requires more stuff?

2. Compare the pressure ratios. Which is larger?

Hints: